ArcelorMittal Poland has invested over PLN 27 m in its plant in Chorzów to produce new, innovative rail profiles that have not been available in Poland so far. As a result, Huta Królewska's customers now include companies from Belgium, the Netherlands, Lithuania, Hungary and Estonia. In addition, the company’s unit in Chorzów also acquired a mechanical marking machine for rails and a new control and measurement block.

Huta Królewska is expanding its product portfolio for the railway industry by new profiles which will be sold among others to Hungary, Lithuania, Latvia and Estonia. All as part of the INNOSTAL programme by the National Centre for Research and Development (NCBR), aimed at increasing the competitiveness and enhancing the innovation of the Polish steel industry.

Production technology of these new railway products developed in Chorzów is characterized by reduced consumption of materials used in the production process - rolls and rolling equipment. Research and development work on this technology started in 2017 and was completed in the middle of this year.

We make unusual orders right away

As part of the project the technology for the production of three innovative railway rails was developed which had not been previously produced in Poland or at any ArcelorMittal plant in the world. - The first rail profile (MAV48) produced under the INNOSTAL project is intended for the Hungarian railways. It has special cross-section parameters that are required on the local market - emphasizes Tomasz Zygmunt, PhD, R&D manager at ArcelorMittal Poland. The first batch of rails of this type has already found its way to Hungary.

The second profile (P50) was produced to meet the needs of the Baltic countries - Lithuania, Latvia and Estonia. This project was not easy because the rails had to be manufactured according to special guidelines - the section of the rails according to the Russian standard, and production according to the European standards. The last type of rail developed under the INNOSTAL programme is the rail (50E2), which will be exported to Belgium and the Netherlands.

- We are investing in our plant in Chorzów because the assortment produced here is desired on the European markets. It is for this reason that we are developing new rail profiles to meet the needs of our customers in rail industry - emphasizes Sanjay Samaddar, chairman and CEO of ArcelorMittal Poland.

USG and PESEL for rails

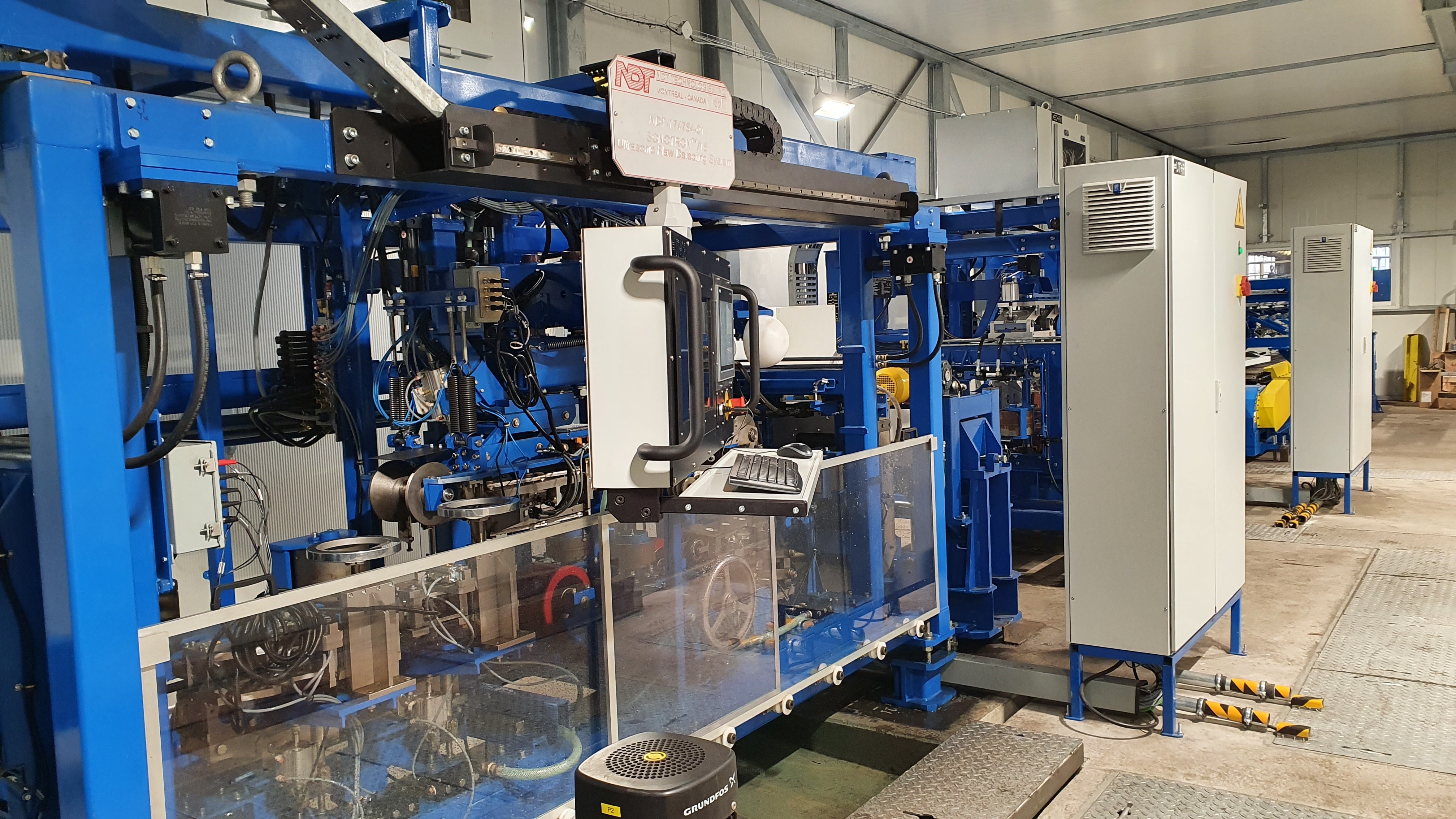

New products are one thing but equally important is the modernization and development of the plant so as to adapt it to the highest standards and norms. Recently, a control and measurement block has been installed in Chorzów, which allows the company to control additional parameters and properties of rails in accordance with European standards. The block checks, i.e., whether the rail is straight and whether it has any surface defects. The last feature is tested by the eddy current method, i.e. the surface of the product is scanned for possible defects that are difficult to see using the traditional method - they cannot be seen with a naked eye. Thanks to the ultrasonic examination, it is possible to quickly detect possible defects inside the rail. It allows to x-ray the inside of the product. This investment is of significant importance - so far rails produced in the Chorzów plant had to be tested at ArcelorMittal Poland’s Unit in Dąbrowa Górnicza, which was complicated logistically and also costly.

In addition to the control and measurement block, a mechanical marking machine has been installed in Chorzów. The device allows the rail code to be punched in a mechanical way, giving the product an individual number, which can be compared to a PESEL number for rails. Thanks to this, it is possible to identify the product in the next stages of processing until it is delivered to the customer.

- Thanks to the installation of new equipment and automation of the rolling line in Chorzów we can constantly expand or product portfolio for the railway industry. New investments adapt our plant to the increasing requirements of customers and the production of rails in accordance with the current European standards - emphasizes Ireneusz Góral, director of ArcelorMittal Poland’s Unit in Chorzów.